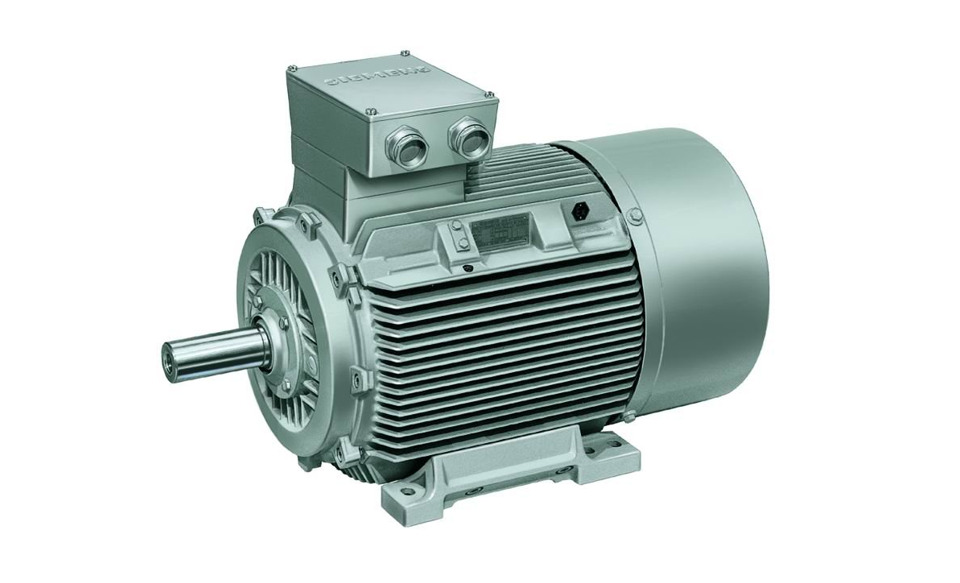

When machines fail and go through the repair process it is important to understand the application. While most are fairly common and insulation upgrades from class B or F to class H are the industry norm, the compatibility with the environment can be an issue. For hermetic systems, such as hermetic compressors, insulation system compatibility is a serious issue.

In an effort to reduce CFCs, hermetic oils such as R-12 (Dichlorodifluoromethane) were replaced by R-22 (Chlorodifluoromethane) and R-134a (1,1,1,2 – Tetrafluoroethane) as common refrigerants. The original change in the 1990s resulted in many issues with previously used systems with refrigerants such as R-12. The newer systems such as R-22 and R-134a are far more aggressive and could result in absorption of the refrigerants and extraction of material (dissolve).

The wire enamel, materials and varnishes need to be confirmed compatible with the associated refrigerants. Many times commercial material tear sheets will state that they are refrigerant compatible yet the testing will relate to R-22 or R-134a. For a majority of applications, this would be satisfactory. However, knowing what refrigerant is in use can avoid the pitfalls of reduced insulation reliability. If a different refrigerant is used then the materials must be confirmed to be compatible with that refrigerant, as each one relates to a different chemical property and different reactions with materials.

All materials must be confirmed including wire enamel, insulation material, and varnishes.