The evolution of electrical power systems has necessitated the development of efficient and reliable transmission mediums. High Voltage Direct Current (HVDC) transmission systems have emerged as a pivotal technology, particularly for long-distance and undersea power transmission. The heart of these systems lies in their ability to efficiently transmit large amounts of electricity over vast distances with minimal losses. However, this capability also presents a significant challenge: ensuring effective insulation.

The insulation of HVDC cables is paramount for several reasons. Primarily, it prevents electrical current from escaping the conductor, ensuring that the power reaches its intended destination. It also safeguards the cable from external environmental factors, such as moisture, chemicals, and physical damage, thus prolonging its operational lifespan. Moreover, effective insulation is crucial for the safety of the surrounding environment and personnel, as it prevents potential electrical hazards.

Materials Used in HVDC Cable Insulation

The choice of insulation material is critical to the performance and reliability of HVDC cables. The most commonly used materials include cross-linked polyethylene (XLPE), and pape-oil insulation.

- Cross-Linked Polyethylene (XLPE): XLPE is favored for its excellent electrical properties, high chemical and thermal resistance, and superior mechanical characteristics. Its cross-linked molecular structure provides enhanced stability under high electrical stress, making it an ideal choice for HVDC applications.

- Paper-oil insulation: This insulation system comprises cellulose paper or Kraft paper wound around the conductor, which is then impregnated with mineral oil. The synergistic combination of paper and oil offers a high level of insulation reliability, with the ability to self-heal minor imperfections due to the fluid nature of the oil. Despite the emergence of synthetic insulation materials, the paper-oil insulation system remains valued for its proven track record, especially in underground and submarine cable systems where longevity and durability are paramount. However, it requires careful maintenance and monitoring to address issues like oil leakage and degradation over time, ensuring the system’s continued efficacy in safeguarding electrical transmission lines.

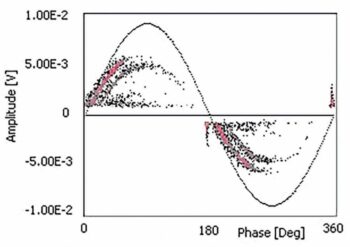

Challenges in HVDC Cable Insulation

While significant advancements have been made in HVDC cable insulation, there remain several challenges. One of the primary issues is the space charge accumulation within the insulation material under high DC voltage. This phenomenon can lead to localized field enhancements, potentially causing insulation breakdown over time. Another challenge is the thermal management of HVDC cables, as the heat generated from electrical losses must be effectively dissipated to prevent overheating and degradation of the insulation material. Moreover, the environmental impact of the insulation materials and the need for their recyclability and sustainability are increasingly becoming areas of concern.

Future Prospects

The future of HVDC cable insulation lies in the development of new materials and technologies that address the current challenges. Nanotechnology offers promising solutions, with nanocomposites being researched for their potential to improve thermal conductivity, reduce space charge accumulation, and enhance the overall performance of HVDC cable insulation. Furthermore, environmentally friendly and sustainable materials are being explored to minimize the ecological footprint of HVDC systems.

Conclusion

HVDC cable insulation plays a critical role in the efficiency, reliability, and safety of high voltage direct current transmission systems. As the demand for clean and efficient energy transmission continues to grow, so does the importance of advancing insulation technologies. By overcoming the existing challenges and harnessing the potential of new materials and innovations, the future of HVDC cable insulation looks bright, promising a more efficient and sustainable electrical power transmission landscape.

DEIS has all the necessary competences to deal with these challenges: for more information, please contact the Technical Committee on HVDC cable System.